Pyrolysis technology has emerged as a revolutionary method for waste management and resource recovery, providing solutions that align with sustainability goals. These machines, designed to process different types of raw materials, vary in structure and operation based on the feedstock they handle. Let’s explore how pyrolysis machines are categorized by the raw materials they process, focusing on three major types: oil sludge pyrolysis plants, waste plastic pyrolysis plants, and waste tire pyrolysis plants.

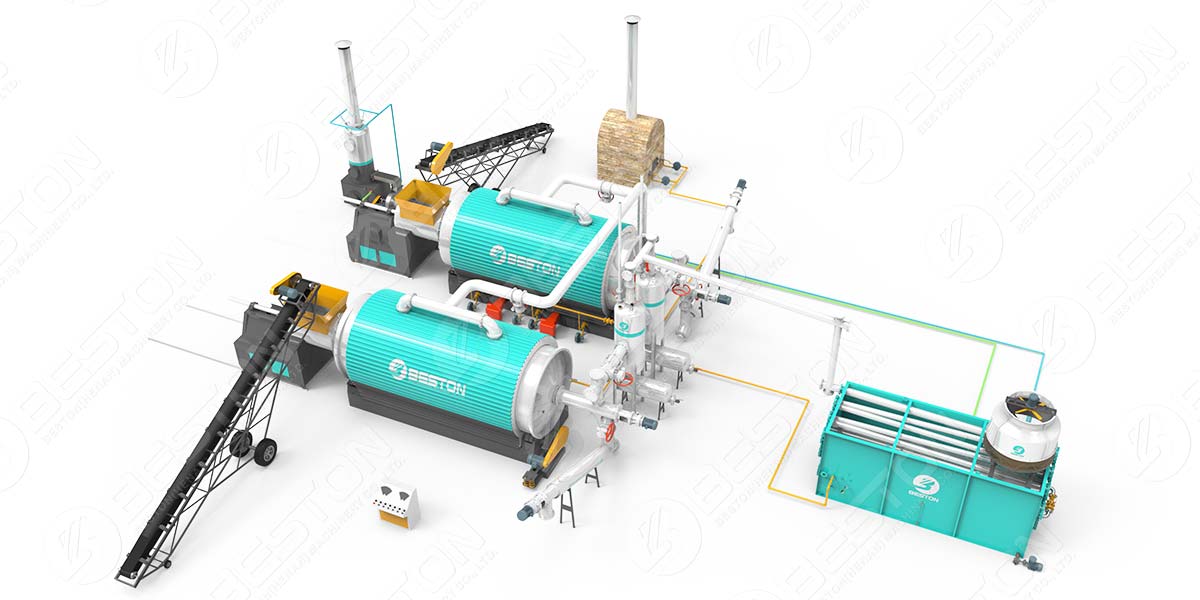

Oil Sludge Pyrolysis Plant

An oil sludge pyrolysis plant is engineered specifically to process oily waste generated from petroleum extraction, refining, and storage. Oil sludge is a challenging waste product because it is a hazardous material composed of a mixture of oil, water, and solids. The pyrolysis process offers an effective solution by breaking down the oil sludge into usable resources such as fuel oil, solid carbon black, and water.

These plants use high temperatures to thermally decompose the sludge without oxygen, converting the hydrocarbons into valuable outputs. The oil sludge pyrolysis plant by Beston Group is highly efficient and features advanced safety mechanisms to handle these toxic materials safely. With this plant, industries can significantly reduce their environmental footprint while recovering resources that can be reused or sold.

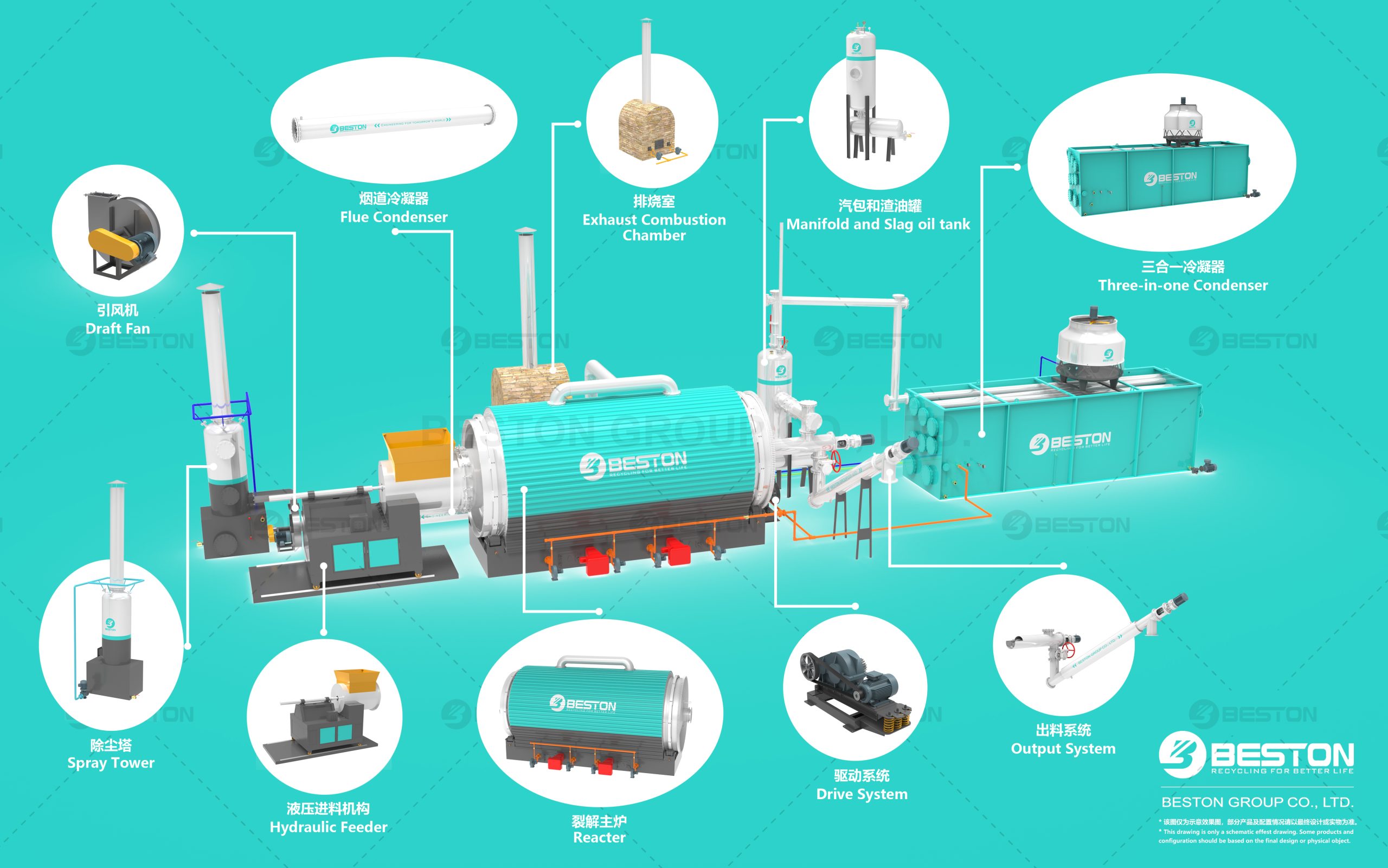

Waste Plastic Pyrolysis Plant

The waste plastic pyrolysis plant is designed to address the growing issue of plastic pollution. Plastics are notoriously difficult to break down naturally, often taking hundreds of years to decompose. However, pyrolysis provides a sustainable method for recycling waste plastics by converting them into useful byproducts like pyrolysis oil, carbon black, and combustible gas.

This type of pyrolysis machine is tailored to handle different kinds of plastics, such as polyethylene, polypropylene, polystyrene, and more. The waste plastic pyrolysis plant from Beston Group is equipped with continuous feeding systems and automated controls, ensuring a high conversion rate and minimal manual intervention. By transforming waste plastics into valuable energy resources, this technology helps in reducing landfill waste and conserving natural resources.

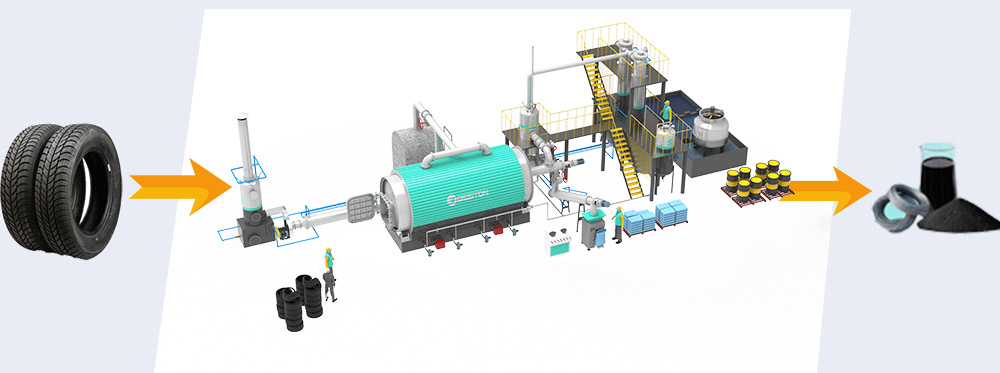

Waste Tire Pyrolysis Plant

The waste tire pyrolysis plant specializes in processing end-of-life tires into fuel oil, carbon black, steel wire, and combustible gas. Tires are a significant environmental concern due to their bulk, durability, and potential to cause pollution. Pyrolysis presents a sustainable solution by breaking down the rubber and other materials found in tires into reusable forms.

The waste tire pyrolysis plant from Beston Group is designed to maximize efficiency and safety. It operates under a controlled environment, minimizing emissions and ensuring that the valuable materials are extracted in their purest form. This plant not only helps in managing tire waste but also provides a profitable avenue for converting waste into marketable commodities like tire-derived fuel and recovered carbon black.

Conclusion

Choosing the right pyrolysis machine depends on the type of raw material to be processed. Whether it is an oil sludge pyrolysis plant, a waste plastic pyrolysis plant, or a waste tire pyrolysis plant, each type offers unique benefits and capabilities. Companies like Beston Group have developed a range of pyrolysis machines tailored to handle different waste streams, helping industries manage their waste more effectively while contributing to environmental sustainability.

By investing in these specialized pyrolysis plants, businesses can turn waste into wealth, reduce their environmental impact, and promote a circular economy. The versatility and efficiency of these machines make them indispensable tools for modern waste management.