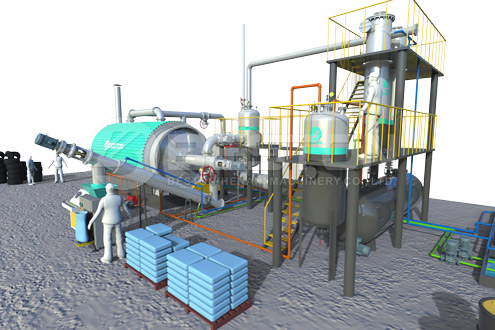

Although people typically reference pyrolysis plants as being a large scale operation, it is possible to get smaller ones if that is all you need. In a way, they are the middle ground, in between the standard pyrolysis plants and pyrolysis machines which are much smaller. For some people, they may have more than enough to run through a typical machines, but they may not have enough material to use with a large-scale pyrolysis plant. Here are the benefits of owning a small scale pyrolysis plant, and the types of materials that you can use with this particular system. Contact reputable manufacturer to get a suitable small scale pyrolysis equipment.

What Can You Use With Pyrolysis Plants?

There are three types of materials, in general, that you can use with the pyrolysis process. This is a process that converts that material into biochar and burnable fuel. Examples of this would be plastic, rubber, and organic materials. These materials can come in many different forms. For example, you may have a landfill that has a substantial amount of plastic bottles, or rubber tires, and these can easily be cut down to size and used in the pyrolysis reactor. If you are a farmer, or if you own a sawmill, the use of husks or sawdust is also possible. Beston Machinery, a waste to energy machine manufactur, has good machine for you.

Why You May Need A Small Scale Pyrolysis Plant

Small scale pyrolysis plants are just as common as large ones. These are used by businesses or individuals that have a medium amounts of materials to use. Instead of having tens of thousands of tires that need to be processed, they may only have a couple thousand tires that they would like to process on a daily basis. The same is true for farmers that are only harvesting small crops instead of those that are on a large-scale. These pyrolysis plants that are smaller will be apropos for these activities which do not produce a substantial amount of material that can be converted into fuel and biochar. See the specifications there https://bestonmachinery.com/rubber-pyrolysis-plant/.

Where To Find Companies That Offer These Smaller Pyrolysis Plants

You can find these pyrolysis plants for sale online. They will be in the midst of the larger ones and also the pyrolysis machines. Most of these will come from a select group of well-known businesses that are known for producing these at a very high level. They are sold worldwide, and these businesses make their money based on volume of sales more than anything else. That’s why they can charge less for them, yet still be top producers and generate a large amount of revenue. By getting estimates or quotes from these businesses, you can find out which one is offering these particular pyrolysis plants at a lower price.

Once you have set up your small scale pyrolysis plant, you can begin to process all of your material. In many cases, they will be easy to expand, allowing you to prepare for the expansion of your business in the future. In five years, you may be producing twice as much organic material, or perhaps you will have access to more plastic and rubber. Either way, it’s a great place to start, and a much more affordable solution, if you want to quickly become a producer of biochar, bio oil, and bio-fuel that can be sold on the market. Click https://flipboard.com/@wastetoenergy/tyre-pyrolysis-machine-for-sale-gcugirdky to see different models.