Several companies sell waste tire to oil plant or a pyrolysis plant. It is a profitable business that helps in converting waste materials such as old tires, plastic and biomass into fuel oil and other products. There are several advantages of investing in tyre pyrolysis plant.

One of the biggest advantages is that it allows you to get rid of waste products that are piling up in landfills. Also, this business can be operated profitably in the long run.

Having said that, a lot depends on your business plan and how you execute various parts of your plan. In this blog post, we will discuss the factors that affect the cost of a waste tire to oil plant:

Daily processing capacity

It is the most significant factor that affects the cost of a pyrolysis plant. The processing capacity ranges from around 2 tons to more than 30 tons a day. In fact, you can get an extremely big processing plant and use it to process material in excess of 100 tons a day. The price obviously increases with the increase in processing capacity.

Configuration

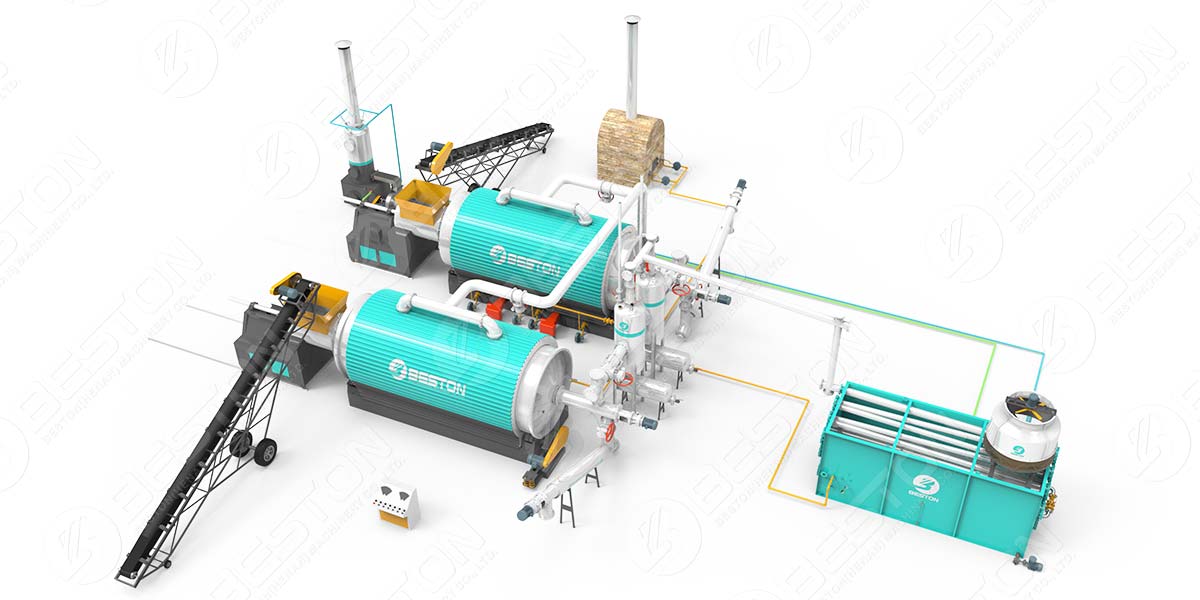

These plants are available in both batch type configuration as well as semicontinuous and fully continues configuration. The large capacity plants are always going to be fully continuous pyrolysis plant keep operating 24 x 7 whereas batch plants typically have lesser processing capacity. This is due to the reason that the reactor needs to be cleaned out after processing of each batch.

Manufacturers

You might be wondering why a manufacturer or brand plays a role in the price of this plant. However, the brand or manufacturer decides the quality of materials used for this plant.

The main part of this plant is the reactor where the pyrolysis takes place. This reactor could be made from average quality materials which essentially means that you will need to replace some components much earlier than expected.

Automation

You can buy these plants in semiautomated as well as fully automated configurations. Both these configurations have their own advantages and limitations. A continuous waste tyre pyrolysis plant is obviously going to be more expensive as compared to a semiautomated configuration but it also ensures fewer errors and better efficiency.

Other Important Parameters

While these are some of the factors that affect the price of a plant, there are certain other important parameters that may not have a huge impact on price but really matter when it comes to overall operations.

You should also check out the type of fuel that can be used for operating the plant, cooling method, operating pressure, overall weight of the plant, overall space required for installation of the plant, expected service life and other such things.

Conclusion

Overall, a waste tire to oil plant is available for sale at various price points. You could buy a standard plant for around $50,000 with a processing capacity of a few tons per day. Bigger plants obviously cost a lot more.

However, it is recommended to focus on long-term profitability of the plant which depends, to a large extent, on the fuel efficiency and maximum yield that can be obtained from the waste tyre recycling plant.