One frequent alternative to the traditional method of producing electricity is the use of a pyrolysis plant that operates continuously. A traditional power generator may struggle to satisfy the requirements set forth by the local government, but this plant is capable of doing so. The following reviews will help you locate the manufacturing plant that is most suited to meet your requirements, regardless of the size of the production facility you require. If you are thinking about buying one of these continuous tire pyrolysis plant, you should think about the expenses involved as well as the requirements for each of the many varieties.

Description

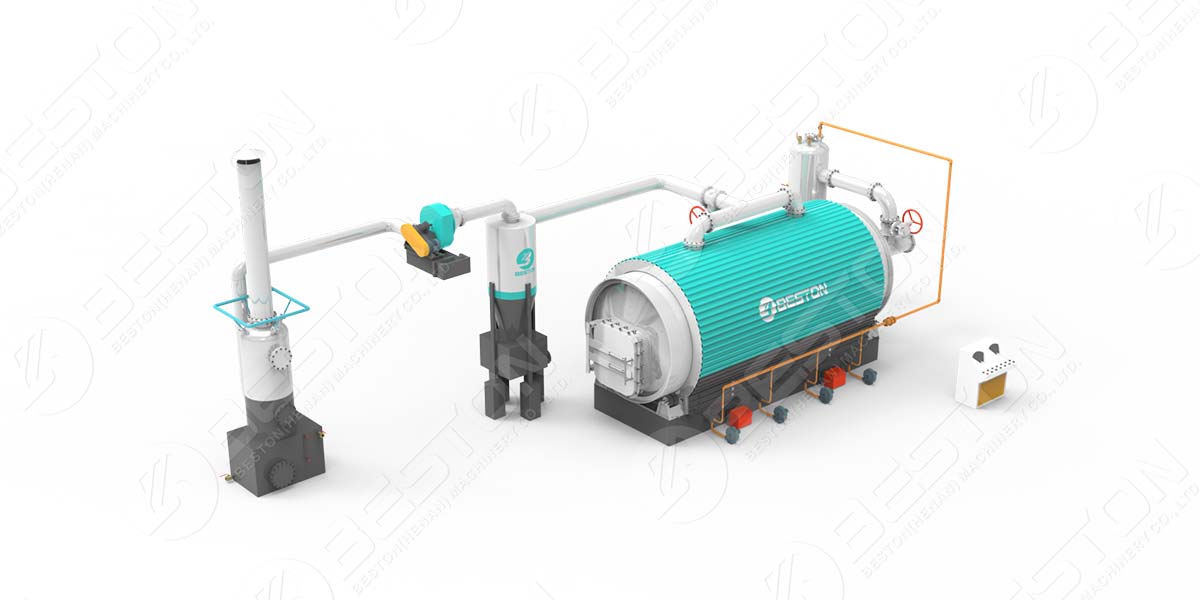

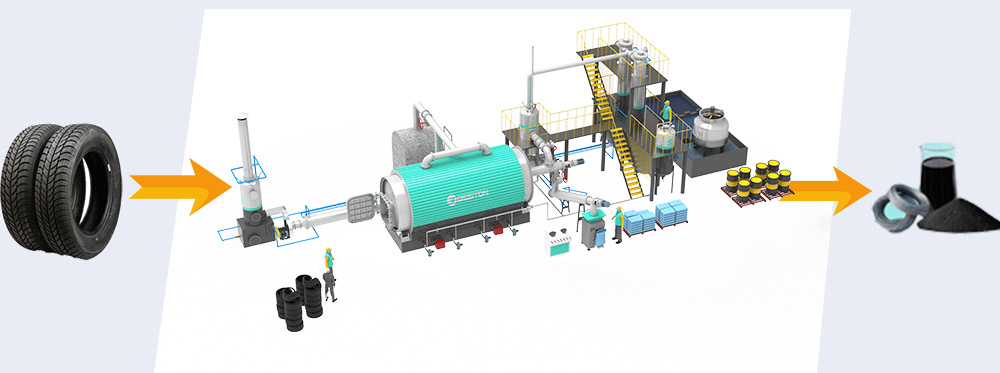

An unique seal design is utilized at the continuous tyre pyrolysis plant to eliminate the possibility of pyrolysis oil gas escaping. This protects both the environment and the manufacturing facilities from any potential hazards. In addition, spent oil may be recycled into diesel or gasoline, which can then be utilized as a fuel in commercial settings. It is also possible to transform it into carbon black, which may then be used into the production of steel rods and steel pads. In addition to this, it has use in the operations of manufacturing steel, namely as a color master batch.

The underlying logic behind it

The burning of carbon-rich materials forms the basis for the continuous pyrolysis plant’s operating concept, which is based on the process of combustion. This method involves the use of heat in order to slowly burn the raw materials. When the temperature within the heating chamber exceeds 100 degrees Celsius, the oil gas is released. When it reaches the condenser, the heavy oil gas turns into a liquid. After that, the lighter gas is let go into the oil tank that is located above. In the last step, the gas that cannot be condensed is passed through a desulfurization system before being introduced into the furnace. Look at this pyrolysis plant in Zimbabwe.

Equipment necessary

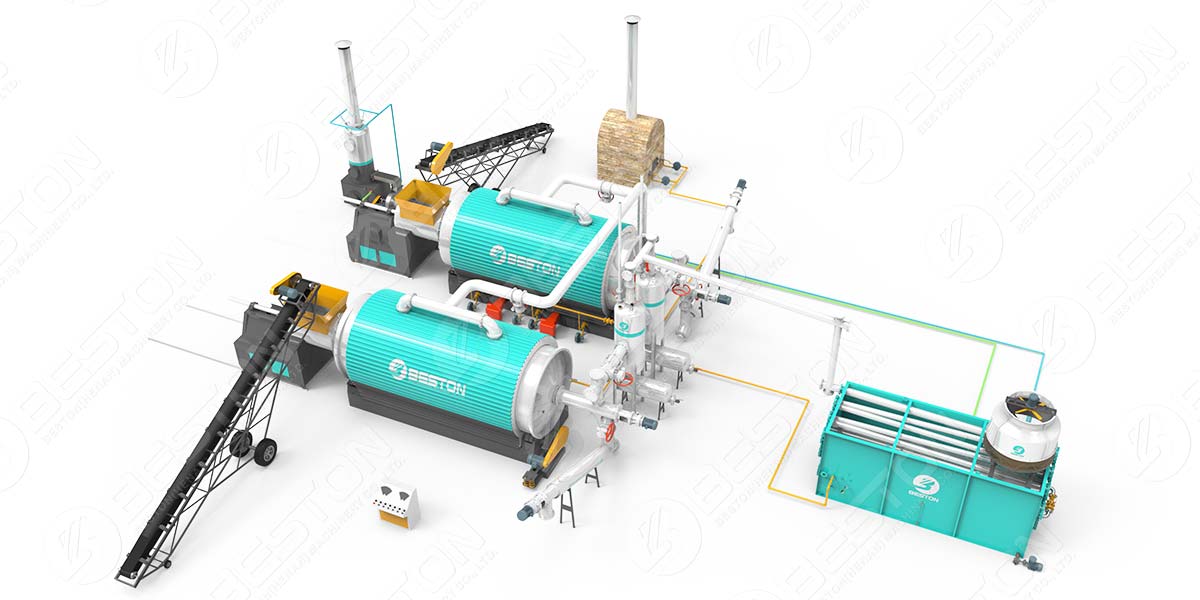

The reactor, the feeder, and the cyclone are the three primary components that make up a facility that performs continuous pyrolysis. Plants that do continuous pyrolysis make use of something called a rotating continuous pyrolysis reactor. This particular kind of pyrolysis plant may pyrolyze as many as two furnaces in a single day, and the cost of manual labor is quite low. This particular category of pyrolysis plant also features an outlet for the discharge of cooled waste.

Cost

When it comes to the bottom line, the investment in a continuous pyrolysis plant is absolutely money well spent. The use of this large-scale industrial equipment may help you save a substantial amount of money, which can be applied to essential expenses such as those for power, water, and land. You may take use of Beston Machinery’s skilled sales advisors to assist you in determining which model is the most suitable for your requirements. The running of a continuous pyrolysis plant is connected with a number of different costs, some of which will be discussed in the following paragraphs.

Application

The type of feedstock that is used in a batch reactor as opposed to a continuous pyrolysis plant is the primary distinction between the two types of plants. The first one is equipped with an automated feeder, whilst the second one does not. Pyrolysis units that operate continuously are preferable for use in the processing of large quantities of raw materials. They are better suited for sectors that demand high production volumes and feedstock of a constant quality. Continuous pyrolysis plant application will not give you any problems as long as you have a consistent supply of raw materials to work with. Contact some pyrolysis machine manufacturers.