The whole egg tray moulding machine adopts domestic first-class brands of water pump, homogenizer, and metal drying line. The electric motor and slurry pump are domestic first-class brands, and the copper content of the electric motor is guaranteed at 100 percent. The six-layer metal drying line reaches the industry’s most advanced energy-saving standard, and has undergone dozens of technical upgrades. The whole egg tray making machine also employs automatic stacking technology, ensuring a higher degree of automation than any other machine.

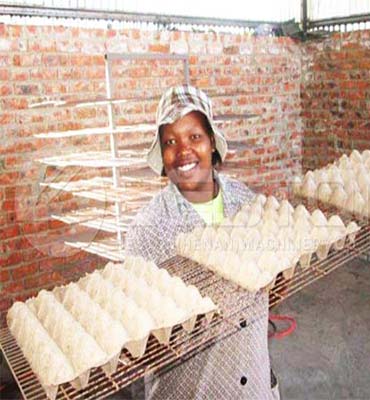

Natural Drying Is the Simplest and Cheapest Method

This is the most basic method of egg tray drying. Natural drying involves placing egg trays outdoors or indoors on a drying rack. Depending on the time and weather conditions, this method can take anywhere from six to seven hours. Compared to automatic metal drying, natural drying does require more labor force and space. It is only suitable for small-scale egg tray machines. A drying cart or rack is available from Beston Group. The main advantage of natural drying is its low cost. Compared to other drying methods, it can save you a lot of money in investment costs and fuel. You can also start with a small-scale egg tray plant using natural drying.

It Is More Cost-effective

An egg carton machine makes it easier and cheaper to make and sell these trays. Paper and cardboard are two of the most common raw materials for egg trays. You can use old newspapers and books, cartons, offcuts from other products, and even used egg trays. These materials come from anywhere in your city, but you should look for one within two hundred kilometers from your place of business.

It Is More Energy-saving

An egg tray making machine uses wood pulp and recycled paper to create reusable trays. Egg trays are a popular way to pack eggs and are an environmentally friendly option to plastic ones. If you are looking to reduce your energy consumption and save money, you may want to consider investing in an egg tray making machine. In addition to paper pulp, you can also use old newspapers, books, and paper pulp. If you have a chicken farm, you can even buy an egg tray making machine to use to pack your eggs. Waste paper is another way to produce egg trays.

It Is Environmentally Friendly

Aside from egg trays, the machine also produces other types of molded products, including paper egg trays, electric crates, and fruit trays. It can be made from biodegradable materials, such as old newspapers or books. It can also be used to create fragile padding, such as boxes for fragile items. Moreover, it is a cost-effective machine, as the smallest one can produce around 1000 paper egg containers per hour. Get competitive egg tray machine price here.

It Uses Only Waste Paper and Water

The process of producing an egg tray involves several processes such as pulping, molding, drying, packing, and packaging. A hydraulic pulper processes the waste paper, resulting in a soft and dry pulp. The finished pulp is then transported to a forming machine for further processing. This process requires constant water supply, which must be clean and drinkable to avoid damaging the end product. After the raw material is processed, the water is recycled for reuse.

It Is A Sustainable Development Business Model

A business model that is designed to address sustainability issues requires that its activities be based on sustainable resources. Many business activities are restricted by finite resources and/or extremely high prices. While some resources are plentiful and cheap, others are damaging to the environment. A case in point is palm oil farming, a cheap, abundant resource that razes acres of land and causes significant environmental damage. To meet these challenges, a sustainable business model borrows resources and reinvests them, ensuring a return on investment and responsible consumption. Check the egg tray manufacturing machine here.