Pulp molding packaging has emerged as a sustainable and versatile solution in the packaging industry. Leveraging advanced pulp molding equipment, this eco-friendly packaging method offers numerous benefits across various applications, from egg trays to industrial packaging. This comprehensive guide explores the multifaceted advantages of pulp molding packaging, emphasizing its environmental, economic, and functional benefits.

Environmental Benefits

1. Sustainability

Pulp molding packaging is predominantly made from recycled paper and cardboard, making it an environmentally sustainable choice. The utilization of waste paper not only reduces landfill burden but also minimizes the need for virgin materials, thus conserving natural resources.

2. Biodegradability

Unlike plastic packaging, which can persist in the environment for centuries, pulp molding packaging is biodegradable. When disposed of, it breaks down naturally, returning to the earth without leaving harmful residues. This attribute significantly reduces environmental pollution and promotes a circular economy.

3. Reduced Carbon Footprint

The production process of paper tray making machine typically involves less energy consumption compared to plastic or polystyrene packaging. Moreover, since the primary raw materials are locally sourced recycled paper products, transportation emissions are also minimized. These factors contribute to a lower overall carbon footprint for pulp molding packaging.

Economic Benefits

1. Cost-Effectiveness

Pulp molding packaging is cost-effective due to the abundance and low cost of raw materials. Recycled paper is readily available and inexpensive, making the production process economically viable. Additionally, advancements in pulp molding equipment have increased production efficiency, further reducing costs.

2. Market Competitiveness

As consumer demand for sustainable products grows, businesses adopting pulp molding packaging can gain a competitive edge. Offering eco-friendly packaging can enhance brand image and appeal to environmentally conscious consumers, potentially increasing market share and profitability.

3. Customization and Versatility

Pulp molding equipment allows for high levels of customization. Manufacturers can produce a wide variety of shapes and sizes, catering to specific product requirements. This versatility extends the application of pulp molding packaging from simple egg trays to complex industrial packaging solutions, accommodating diverse market needs.

Functional Benefits

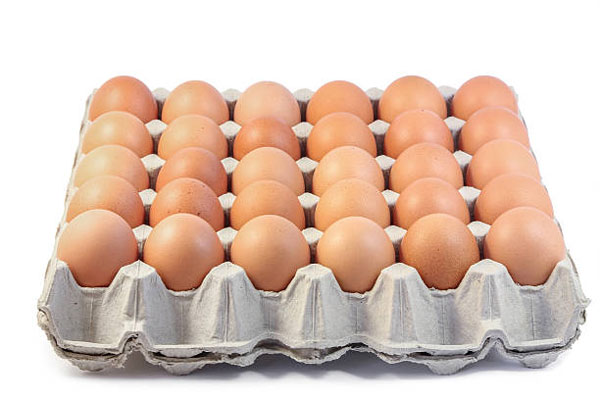

1. Protection and Cushioning

Pulp molding packaging provides excellent protection and cushioning for products. The material’s inherent shock-absorbent properties safeguard delicate items during transportation and handling. For example, pulp-molded egg trays effectively prevent eggs from cracking, ensuring they reach consumers intact.

2. Durability and Strength

Despite its lightweight nature, pulp molding packaging is remarkably durable and robust. It can withstand significant weight and pressure, making it suitable for industrial packaging applications. Heavy machinery parts, electronics, and other fragile items can be securely packaged using pulp molding solutions.

3. Moisture Resistance

Pulp molding packaging can be treated to enhance moisture resistance. This treatment ensures that the packaging maintains its integrity even in humid or damp conditions, protecting the contents from potential damage. This feature is particularly beneficial for food packaging and other moisture-sensitive products.

Applications of Pulp Molding Packaging

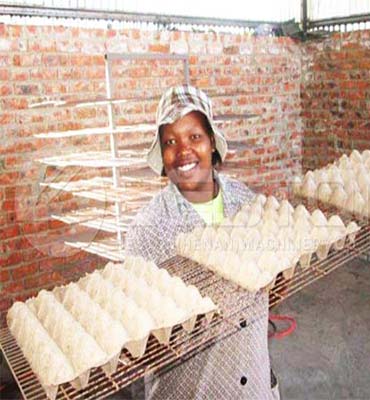

1. Egg Trays

One of the most common applications of pulp molding packaging is in the production of egg trays by paper egg tray making machine. These trays offer a sustainable and protective solution for transporting eggs. The design ensures that each egg is individually cradled, minimizing movement and reducing the risk of breakage.

2. Food Packaging

Pulp molding packaging is widely used in the food industry. From fruit trays to takeout containers, its biodegradable nature makes it an ideal choice for food packaging. It is safe for direct contact with food items, ensuring that no harmful chemicals leach into the food.

3. Industrial Packaging

The adaptability of pulp molding equipment allows for the creation of custom industrial packaging solutions. Companies can design and manufacture packaging that fits their specific product dimensions and protection requirements. This customization is invaluable for packaging electronics, automotive parts, and other high-value items.

4. Consumer Goods Packaging

Pulp molding packaging is also gaining popularity in the consumer goods sector. It is used for packaging items such as cosmetics, personal care products, and household goods. The aesthetic appeal of pulp molded packaging, coupled with its sustainability, enhances product presentation and consumer satisfaction.

Technological Advancements in Pulp Molding Equipment

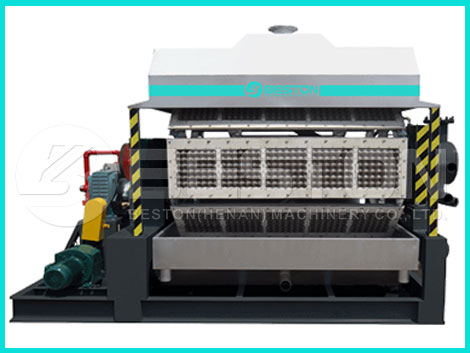

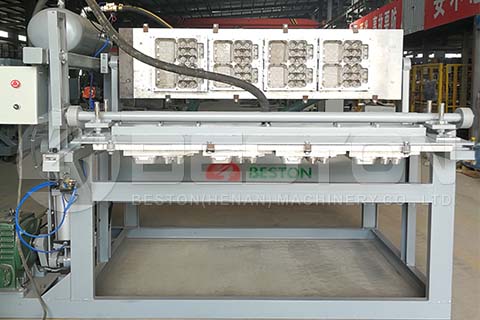

1. Automation and Efficiency

Modern pulp molding equipment incorporates advanced automation technologies that increase production speed and consistency. Automated systems reduce manual labor requirements, lower production costs, and enhance product quality by ensuring uniformity in each batch.

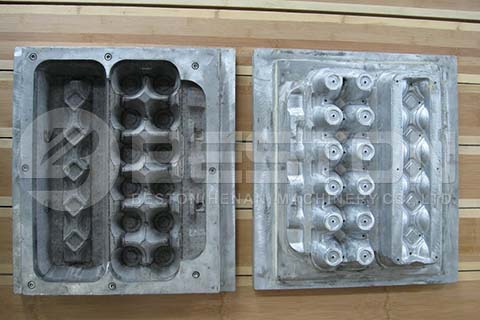

2. Precision and Customization

Technological advancements have enabled greater precision in the molding process. Sophisticated machinery can produce intricate designs with high accuracy, catering to specific client needs. This precision is crucial for creating customized industrial packaging solutions that offer optimal protection.

3. Energy Efficiency

Newer pulp molding equipment is designed to be energy-efficient, reducing the overall environmental impact of the production process. Energy-efficient machines consume less power, contributing to lower operating costs and a smaller carbon footprint.

Environmental Compliance and Regulations

1. Regulatory Support

Governments worldwide are increasingly promoting sustainable packaging solutions through regulatory support and incentives. Pulp molding packaging aligns with these regulations, helping companies comply with environmental standards and avoid potential penalties.

2. Certification and Standards

Products made from pulp molding packaging can obtain various environmental certifications, such as FSC (Forest Stewardship Council) certification. These certifications provide assurance to consumers about the sustainability and environmental responsibility of the packaging, enhancing brand reputation.

Future Prospects of Pulp Molding Packaging

1. Innovation and Development

Ongoing research and development in pulp molding technology are paving the way for new applications and improved performance. Innovations such as enhanced material properties, advanced coating techniques, and integrated smart features are expanding the potential uses of pulp molding packaging. Advanced technology keeps your project running smoothly. Therefore, a manufacturer with strong R&D levels is particularly important. Beston is recommended to you here.

2. Market Expansion

The demand for eco-friendly packaging solutions is expected to grow exponentially in the coming years. Pulp molding packaging is well-positioned to capitalize on this trend, with its sustainable attributes and versatile applications making it a preferred choice for businesses across various industries.

3. Consumer Awareness

As consumer awareness of environmental issues increases, the preference for sustainable packaging solutions will continue to rise. Pulp molding packaging, with its clear environmental benefits, is likely to become the standard for conscientious consumers, driving further market adoption.

Conclusion

Pulp molding packaging offers a plethora of advantages, making it an exemplary choice for businesses seeking sustainable, cost-effective, and functional packaging solutions. Its environmental benefits, economic viability, and versatile applications position it as a leader in the packaging industry. By investing in advanced pulp molding equipment and embracing this innovative packaging method, companies can achieve both their sustainability goals and their business objectives. The future of packaging lies in sustainable solutions, and pulp molding packaging stands at the forefront of this transformative shift.