In recent years, there has been a growing awareness that the Earth has limited resources and that there might not be enough to go around as populations continue to grow exponentially. To fight this, researchers have been searching for ways to utilize the planet’s waste in a more efficient manner.

The continuous waste tyre pyrolysis plant (planta pirolisis de llantas)has been used to efficiently turn old tires into a useable commodity that can substitute for oil and other fossil fuels. Many countries have already adopted this technology to supplement their energy needs, with more considering it.

What is Pyrolysis?

Pyrolysis is a process that converts organic substances into more valuable materials such as hydrocarbons or synthetic crude oil. Pyrolysis may thermally degrade organic substances at elevated temperatures to produce oil, gas, and solid residue (char). This is done without combustion, as the oxygen needed for burning is absent. Pyrolysis(planta de reciclaje de neumaticos) is also used to break down organic matter in the absence of oxygen.

When oil, gas, or coal are burned, they go through a similar process called rapid oxidation. This results in carbon dioxide and water being given off as exhaust byproducts.

How Does the Continuous Waste Tyre Pyrolysis Plant Work?

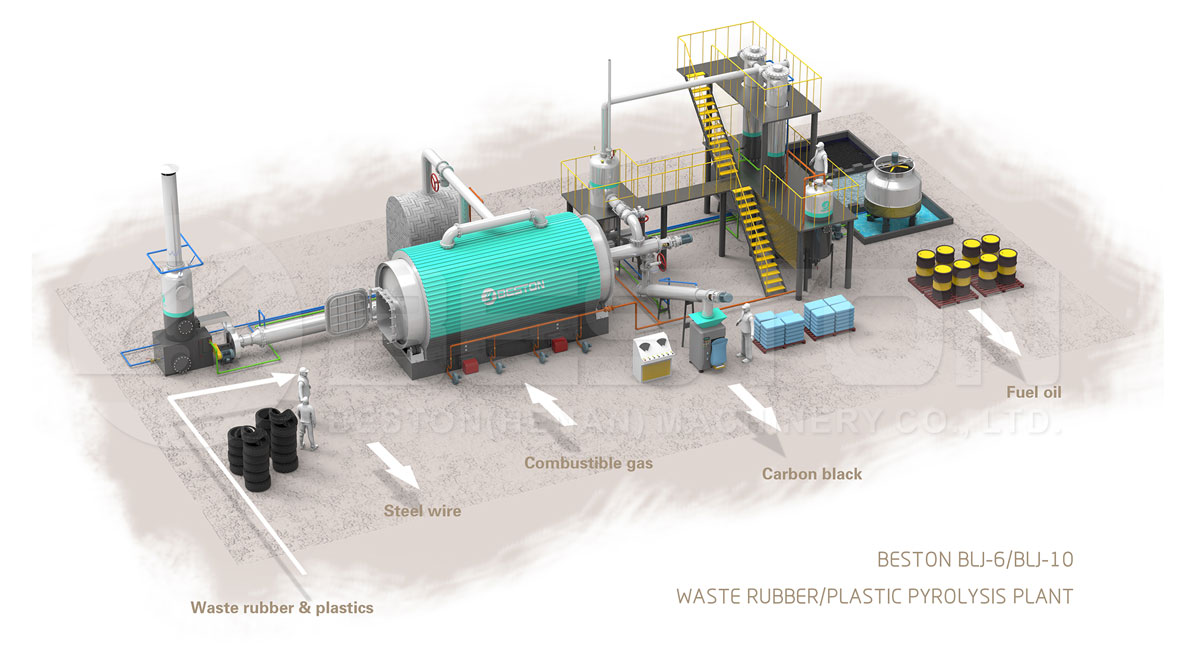

A continuous waste tyre pyrolysis plant(https://www.bestoneco.com/planta-de-reciclaje-de-neumaticos/) is a large industrial machine that can turn old tyres into a synthetic crude oil substitute. The process itself works by heating the rubber tires under controlled temperatures between 500-700 degrees Celsius, alongside the creation of steam and carbon dioxide as byproducts. These gases are then recycled back to help power the pyrolysis process.

The heat causes the polymers in the tires to split apart, creating smaller molecules that are used to make two synthetic crude oils. These are then separated from one another through distillation.

These synthetic crude oil substitutes are very useful due to their similar composition to petroleum. This allows them to be utilized for a wide range of industrial tasks, including generating electricity.

What Are the Benefits of Using Waste Tyres to Produce Oil Substitutes?

Using waste tyres instead of oil has many benefits. For example, it is much more sustainable than traditional oil extraction methods because it does not require drilling into the Earth’s surface. Additionally, there is no risk involved in this process because it uses steam and not water for production. This means that no chemical-laden wastewater will be left to pollute the planet when the process is complete.

Another benefit is that there are already over 250 million waste tyres in landfills in America alone, making it an excellent source of material for this purpose. Even better, used tyres have a higher heating value than other types of biomass, making them an excellent source for energy production.

Waste tyre recycling not only helps the environment but also saves energy. Plus, used tyres are often of higher quality than new ones, meaning they will run more smoothly and last longer. This means that the continuous waste tyre pyrolysis plant benefits businesses as well as nature and the environment.

The continuous waste tyre pyrolysis plant(Proveedor de China – BESTON) is a valuable piece of equipment that can be used to convert an unlimited amount of scrap tyres into clean energy. This process is good for the Earth, saves businesses money, and creates new jobs in communities worldwide.