Waste and the manner whereby we dispose of it is not always a topic people are eager to discuss. Unfortunately, as the issues of environmental protection and climate change are increasing in significance, it becomes necessary to examine the disposal of solid and liquid waste. The majority of people view basic recycling as good enough to combat climate change, but there is much more involved in waste management. This article will provide information on automatic waste segregator and their effect on global warming.

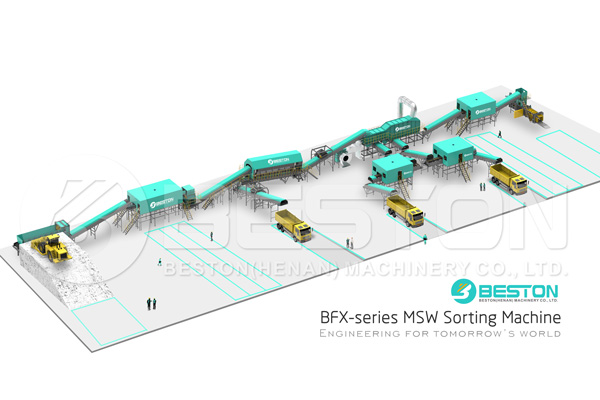

What Is A Waste Segregator Machine?

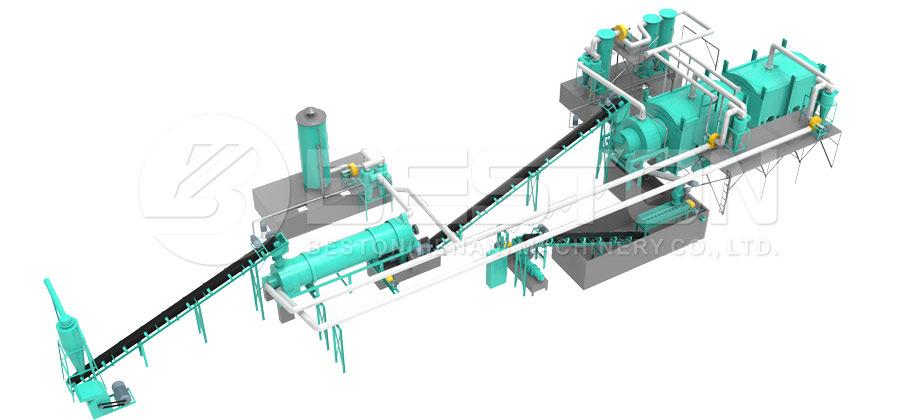

An automatic waste sorter can also be known as a garbage sorting machine. It operates by separating the larger items of solid urban waste, including branches, furniture, bags and sand, from the uniform feed. Uniform distribution lays a foundation for the following processes, including breaking bags, sorting the items, and sorting of the waste – all essential for proper recycling. It is also important to note that the initial sorting divides organic from inorganic matter preparing waste for the next treatment process.

What Are The Applications Of The Sorted Waste Products?

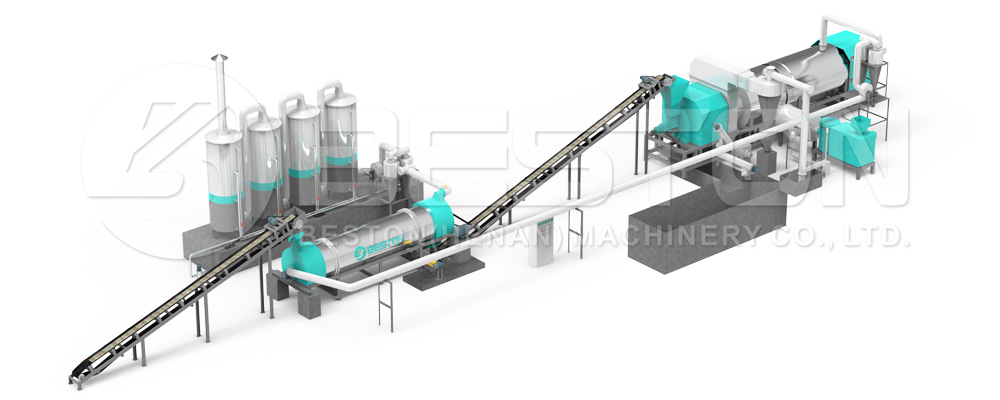

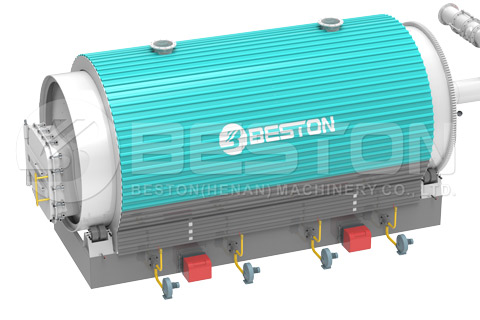

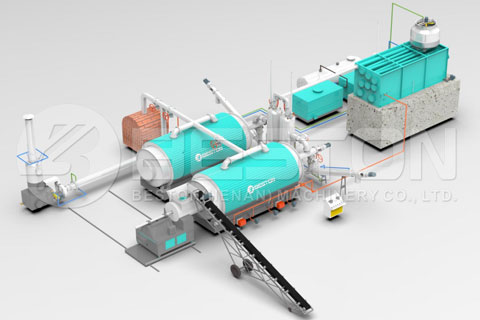

When the garbage separator machine has sorted waste, they can be recycled via reproduction. For instance, plastic waste can be processed into fuel oil or carbon black at plastic waste pyrolysis plants; thereby, increasing the economic value of the waste. It is also possible to recycle plastic granules using advanced plastic recycling machinery. Organic material is typically processed into natural fertilizer to improve the quality of soil. Moreover, residual solid material can be recycled or sold to brick manufacturers for construction purposes. For paper recycling, you can choose https://www.bestongroup.com/egg-tray-machine/.

What About Waste Segregation And Global Warming?

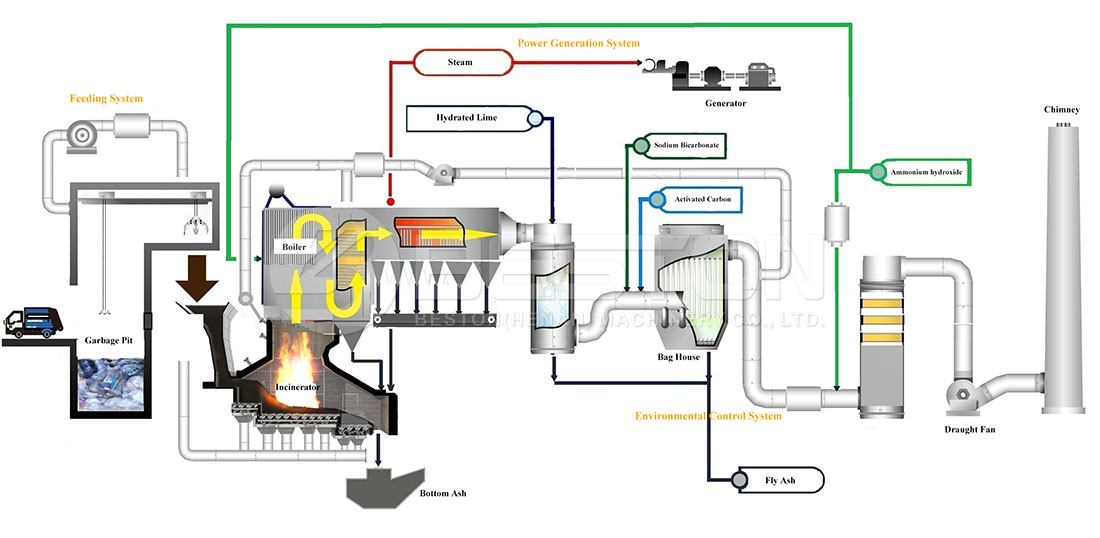

As is mentioned above, waste disposal plays a role in global warming and climate change. This is due to specific waste disposal techniques consuming fossil fuels and producing greenhouse gases. For instance, waste dumped in landfills will release pollutants resulting in methane and carbon dioxide. Incineration of waste can also promote greenhouse gasses as it mixes pollutants with natural oxygen. To lessen the consumption of these fossil fuels, it is necessary to operate incineration machinery and reduce the contaminants used in the disposal process.

The best way for garbage segregation machine to reduce global warming is by reusing, recycling and reduction of fossil fuels. Nowadays, almost all suburban communities have areas for recycling services. All you need to do is dispose of your waste in this area using the correct recycling method. You must separate the items appropriately to ensure the garbage system reproduces items using the right system (as is mentioned in the paragraphs above). By merely taking time out to separate your solid waste, you can contribute to a reduction in global warming.

The Final Words On The Matter

Waste segregation is not something people consider on a daily basis. In fact, waste segregation is an issue that is barely recognized as significant by most individuals. Unfortunately, by not taking note of this issue, the planet is suffering devastating effects. Using the information above, you can contribute to recycling and ensure garbage sorting systems efficiently reproduce the products: https://beston-group.business.site/.