The process of refining sugar involves cutting up sugarcane into small pieces and then crushing it to extract the juice. After the process is over, the leftover pulp from the sugarcane, which is known as bagasse, is usually discarded. Learn more here: www.bestongroup.com/.

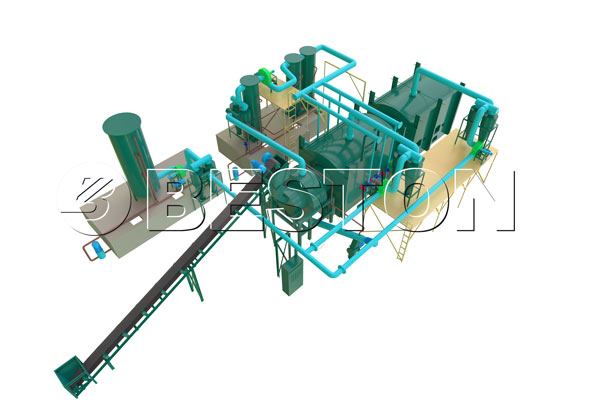

Imagine how much less organic waste would result from the sugar making process if the sugarcane pulp could be put to some kind of use rather than being thrown away. As it turns out, it can. There are machines available on the market that are capable of making charcoal from bagasse. The resulting briquettes can be used as fuel for a variety of different purposes, making it a great way to reuse a product that otherwise would have been thrown away.

The process of making charcoal from bagasse is relatively simple. First, the bagasse needs to be thoroughly dried out. Depending on the complexity of the charcoal making operation, this can be done in a couple of different ways. For smaller operations, the bagasse is usually laid out in the sun to dry for a couple of weeks. This is a simple solution that gives great results without requiring any additional power.

Larger charcoal making machine suppliers may need to process the bagasse more quickly. Additionally, they usually deal with a much larger volume. As a result, they usually dry the bagasse in specialized machines that help remove the moisture rather than allowing it to dry naturally in the sun. This speeds up the drying time and allows them to create the finished charcoal briquettes much more quickly.

After the bagasse is dry, it is then transferred to a specialized charcoal kiln where it is heated to a high temperature. There is very little oxygen inside the chamber. This turns the bagasse into a black charcoal powder.

After the carbonization process is done, the powder is then formed into briquettes using a specialized machine. It is usually then put into bags so that it can be transported to stores and sold to the public.

Traditional charcoal is made from wood. Unfortunately, trees take an extremely long time to grow. They also are in short supply in certain parts of the world.

Sugarcane, on the other hand, grows much more quickly. As a result, it is a much more eco-friendly source for making charcoal.

Finally, after the charcoal briquettes have been used, the resulting ash can be added to the soil as a fertilizer, helping new plants to grow. Ash from biochar like sugarcane bagasse briquettes can help enrich the soil, making it much more capable of supporting plant life. Get the biochar production equipment today.

Transforming bagasse into charcoal briquettes is a great way to give a product that would otherwise be discarded new life. Instead of throwing the bagasse away, it can be turned into an eco-friendly fuel source that helps save trees and reduces society’s reliance on fossil fuels. Now you can contact Beston Group to get more professional information about making charcoal from bagasses.