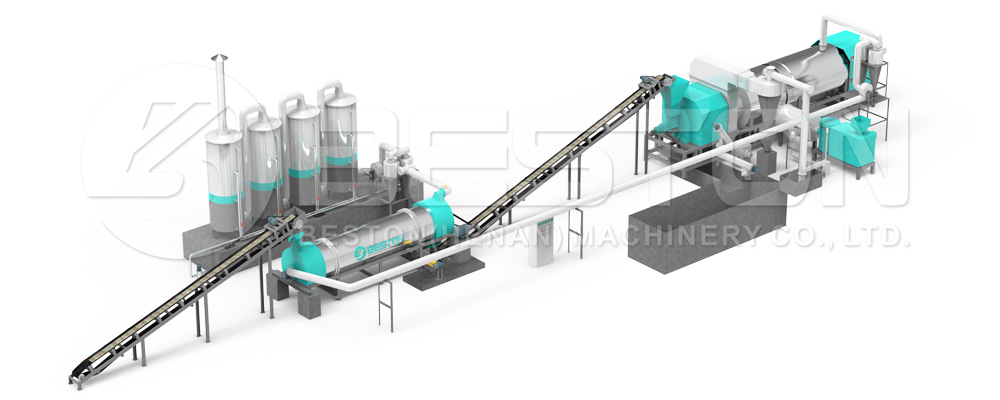

There are many materials that can easily be converted into biochar with the right machinery, including rice husks, wood chips, and bamboos. These kinds of materials don’t have to go to waste. Instead, they can be transformed into something useful. With that said, you’ll want to make sure you buy the right kind of biochar production equipment.

Evaluate Your Needs

There are so many different types of biochar equipment on the market, which is why you can’t assume that any of the equipment that you’re looking at will work for you. Prior to making any purchasing, you’ll want to think carefully about what you’re going to be doing with that equipment.

What kinds of materials are you going to be converting into biochar? How much charcoal do you need to produce each day? These are the kinds of questions you need to be able to answer. Take stock of your needs so that you can purchase equipment that meets all of those needs. More information on coconut shell charcoal making machine here.

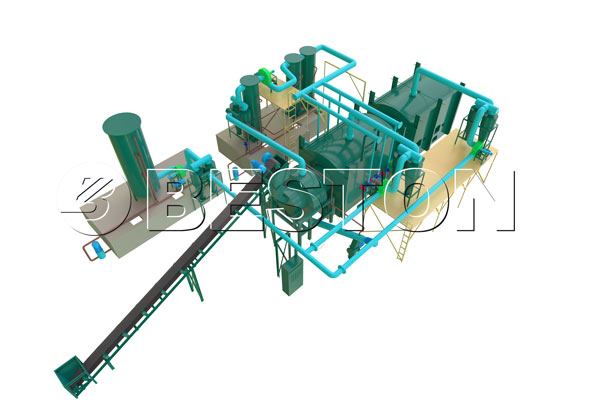

Consider Purchasing A Full Production Line

It’s possible to purchase the equipment that you need for your production line piecemeal. However, you might wind up having a better experience if you buy a full production line. If you’re able to buy all of the equipment that you need in one place, you won’t have to make multiple purchases.

Furthermore, buying a full production line means that all of the equipment you’re buying is designed to work together. It could save you time and money, and it could also wind up saving you a lot of hassle.

It’s a wise idea to educate yourself about the manufacturers that produce this kind of machinery. Of course, manufacturers around the world make biochar equipment, and you may not have the time to read up on every single manufacturer. Instead, you should focus on the charcoal machine manufacturer that makes the products that you’re interested in.

You can find a wealth of information about these manufacturers online. Look for manufacturers that have a long history. Read reviews for their products so that you can see if people have positive things to say about them. If you arm yourself with information, deciding what to buy will be easy.

Look For Warranties

Ideally, you should always try to purchase wood charcoal making machine that is under warranty. A warranty is more than just a piece of paper. It’s something that can protect you if you have problems later on.

Of course, you can’t assume that all warranties are the same. You should also take a closer look at warranties so that you can see what they include. If you’re able to find detailed warranties that provide plenty of coverage, you’ll know that your purchase will be secure.

If you’re interested in converting a material into biochar, you’ll want to make sure that you have all of the equipment that you need. You should take care when purchasing this equipment. Follow the advice above so that you can avoid potential setbacks when you’re buying the machinery that you need.