As global attention shifts toward sustainable development and carbon reduction, the production of biochar is emerging as a compelling green investment opportunity. Biochar not only offers environmental advantages but also delivers tangible economic returns, especially in agriculture, energy, and waste management sectors. This article explores the core reasons why investing in biochar production is a wise move in today’s eco-conscious world.

Eco-Friendly Response to Waste Management Challenges

One of the primary motivations behind investing in biochar production is its ability to convert organic waste into valuable products. Agricultural residues, forestry waste, and biomass materials are often discarded or burned, contributing to pollution and wasted resources. Through thermal decomposition, biochar systems transform these materials into carbon-rich products that enrich the soil and reduce greenhouse gas emissions. This aligns with global efforts to promote zero-waste principles and reduce dependence on landfills.

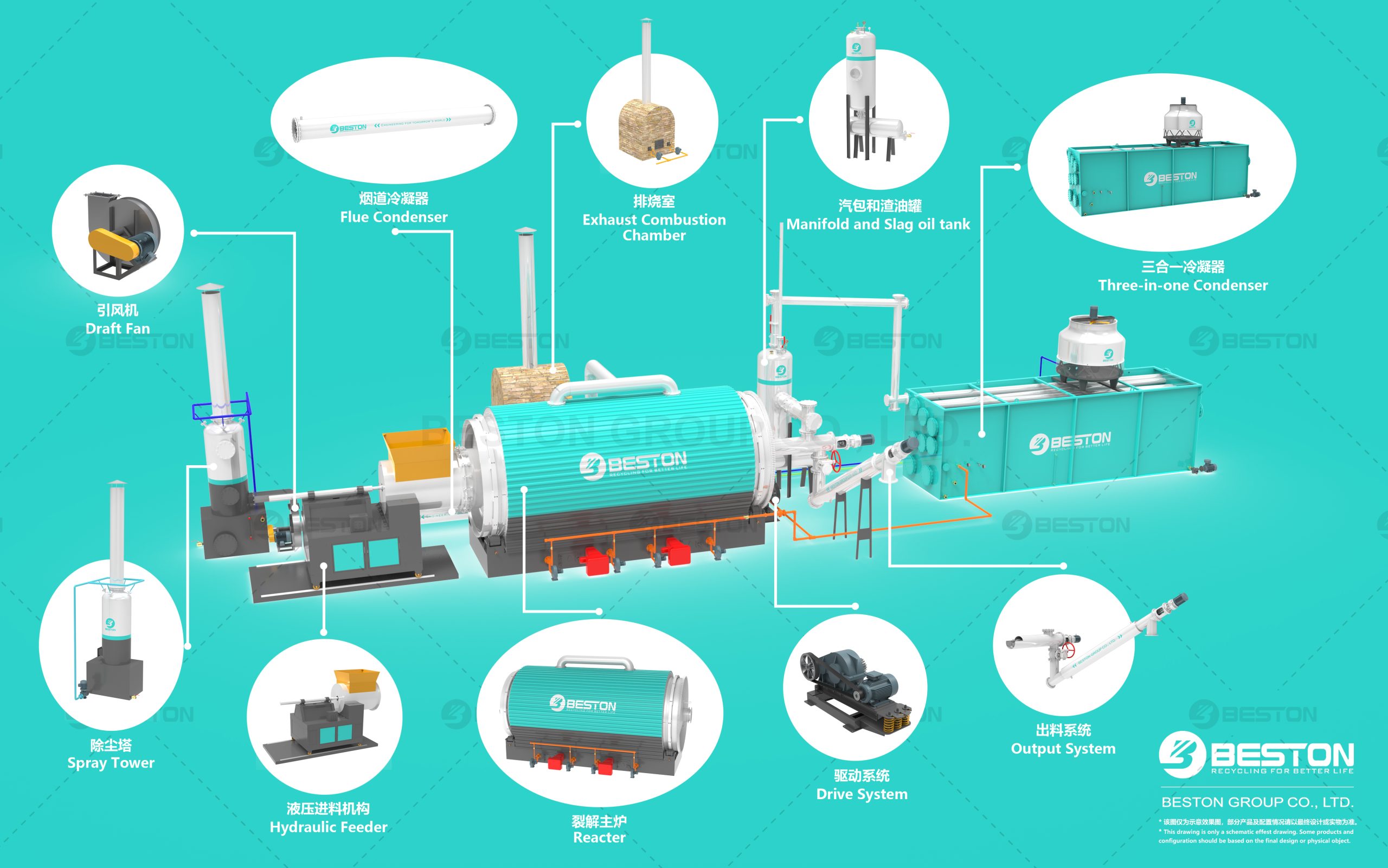

Modern technologies like the biochar making machine have made this process highly efficient, scalable, and adaptable to different feedstocks. From coconut shells to peanut husks and sawdust, a wide range of raw materials can be reused for biochar production, helping investors tap into local waste resources and turn them into revenue streams.

Carbon Sequestration and Climate Action

Biochar is widely recognized as a powerful tool for carbon sequestration. Unlike other carbon offset methods, biochar locks carbon in a stable form and stores it in soil for hundreds of years. By doing so, it reduces the carbon footprint of farming and industrial operations while helping governments and corporations meet their carbon neutrality goals. For climate-conscious investors, biochar offers a practical solution to support decarbonization while generating profit.

Strong Demand in Agricultural Markets

The agricultural sector is among the largest consumers of biochar, and the demand continues to grow due to its benefits for soil health. Biochar enhances soil aeration, improves water retention, and increases nutrient availability, all of which boost crop yields and reduce the need for chemical fertilizers. Organic and regenerative farming practices are on the rise, and biochar fits perfectly into these models.

Investment in biochar production can also be tailored to specific feedstocks. For example, using a straw charcoal machine allows agricultural waste to be turned into biochar right at the source, saving transport costs and offering on-site value addition.

Versatility in Product Applications

Beyond soil amendment, biochar has applications in water purification, livestock farming, construction materials, and energy generation. This versatility broadens its market potential and creates multiple revenue streams for investors. Additionally, by-products like wood vinegar and syngas can be harvested during the production process, further increasing profitability.

For instance, a wood charcoal machine can process forestry residues into not only biochar but also clean energy, which can be used to power rural communities or sold as a renewable energy source.

Scalability and Business Flexibility

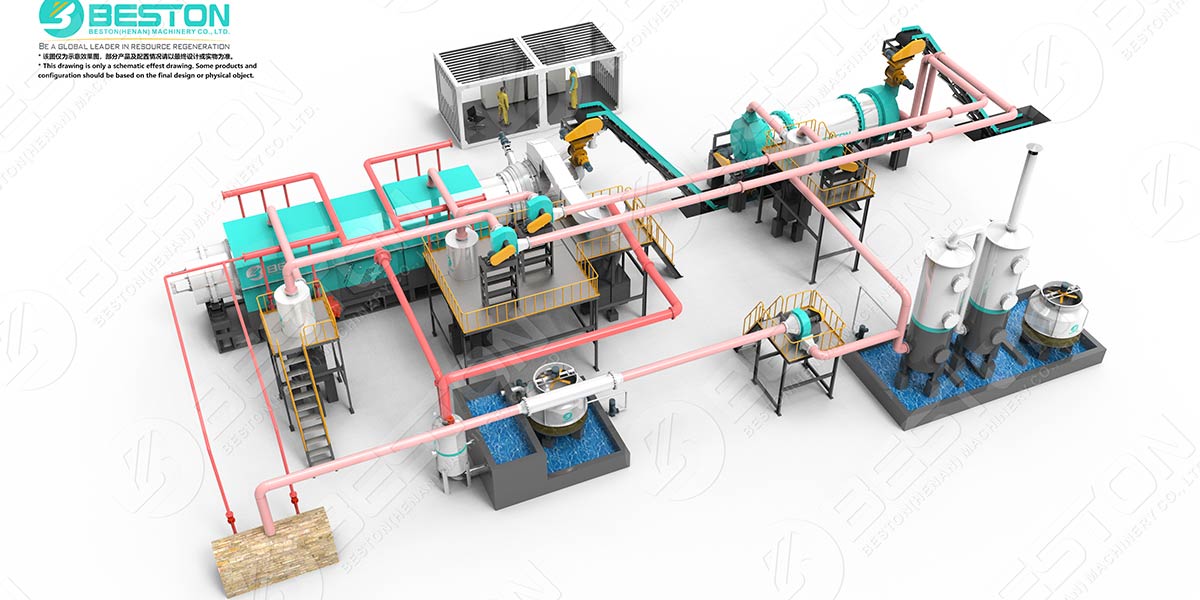

Biochar production systems range from compact models suitable for small farms to fully automated plants capable of processing tons of biomass daily. This flexibility allows investors to enter the market at various scales, depending on their budget and local resource availability. Small-scale models are ideal for starting local businesses or community initiatives, while large-scale plants can serve regional markets or industrial clients.

To complement this versatility, value-added products like compressed biochar blocks can be created with a charcoal briquette making machine. These briquettes are widely used as clean cooking fuel in households and commercial kitchens, particularly in regions where firewood and fossil fuels are expensive or environmentally damaging.

Favorable Government Policies and Carbon Markets

Governments worldwide are actively promoting green investments and offering incentives for carbon capture technologies. Many regions provide subsidies, tax breaks, or carbon credits for biochar producers. In addition, voluntary carbon markets offer new income channels for certified biochar projects, allowing investors to monetize their carbon reductions. By participating in such programs, biochar businesses can enhance their ROI and strengthen their environmental credentials.

Future-Proofing with Sustainable Innovation

As climate regulations tighten and consumer preferences shift toward sustainable products, early investments in biochar production position businesses to lead in the green economy. Biochar is not just a short-term trend—it is a cornerstone of regenerative agriculture, climate-smart infrastructure, and low-carbon innovation. Investors who embrace this technology today are likely to benefit from long-term growth, reputation gains, and environmental impact.

Conclusion

Biochar production is an investment that makes both economic and ecological sense. It addresses critical challenges such as waste management, carbon emissions, and soil degradation while opening doors to multiple income streams and government support. Whether you’re a green entrepreneur, an agricultural investor, or a sustainability-focused corporation, the biochar sector offers a rewarding pathway to contribute to the planet and profit simultaneously.